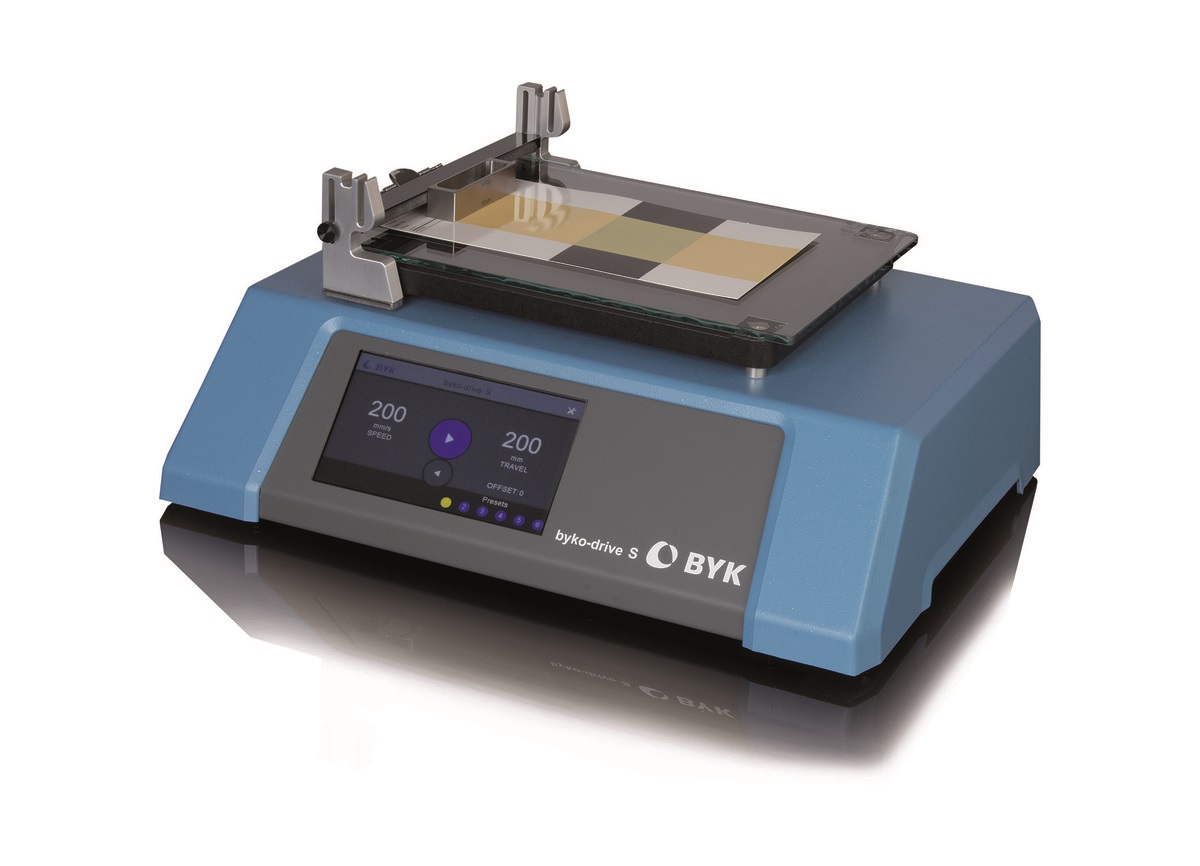

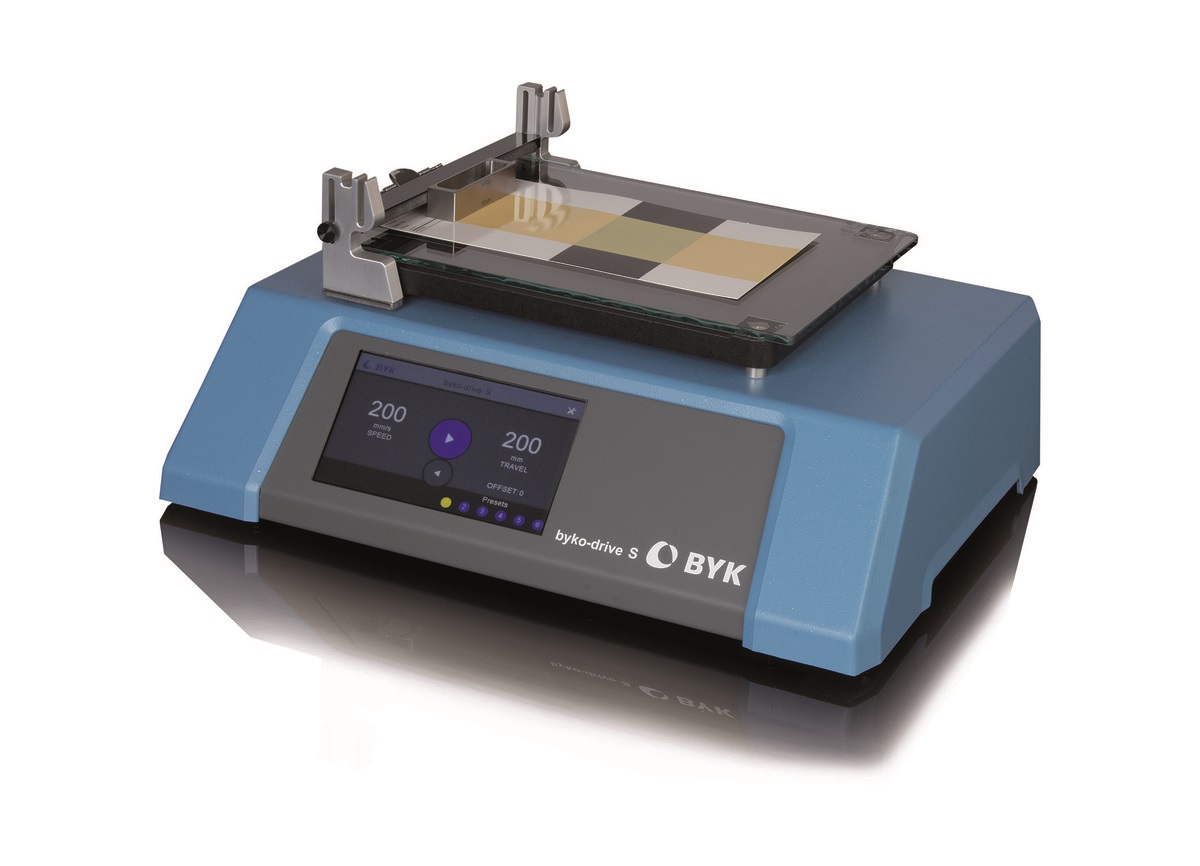

byko-drive S

Automatic Film Applicator

Standards:

| ASTM | D 823 | D4147 |

Cookies helfen uns bei der Bereitstellung unserer Website. Durch die Nutzung der Website erklären Sie sich damit einverstanden, dass wir Cookies setzen.

Standards:

| ASTM | D 823 | D4147 |